Epoxy Powder Coating Give Optimal Hardness and Chemical Resistance

Performance

Epoxy Powder Coating prevents flooring from rust and

deterioration, making commercial flooring finishes widely used. Pure Epoxy

Powder Coatings suitable to provide optimal hardness and a protective

chemical resistance to your products. Epoxy

coating are applied over concrete floors to provide a high-performance,

smooth, and durable surface that can last many years and withstand heavy loads.

Zigma Paints Pvt. Ltd. is

producing Epoxy Paint for all product categories. We understand a great

product and enhances the position of our market through standardized,

tailor-made and efficient solutions.

Epoxy Powder Coating may cost more than other types

of coating materials, its ability to provide superior and durable corrosion

resistance and flexibility to apply coating when materials are prepared

well. They are Protective purposes of pipelines having good chemical

resistance. Mostly these Coating are recommended for items like water immersed

merchandise, laundry machines, chemical pipelines, and others. Zigma Paints Pvt. Ltd. is a reputable company that manufactures and supplies these Epoxy powder coatings.

Applications

of Epoxy Coating

Heating and Lighting Equipment,

Electrical Appliances, Metal Furniture, Office Equipment, Work Tools, Test

Equipment, Lighting Equipment, Internal Auto Components, Household Utensils,

Display Stands, Cabinets, Consoles, Instrument Panels, Castings, Fire

Extinguishers, Hospital Equipment, Laboratory Equipment.

These

Coating have smart static charging properties and potency to transfer

comfortably. It is recommended for industrial parts and equipment that need a

spherical coating. This epoxy powder coating usually gives good protection against the impact of

corrosion and abrasion.

Epoxy Coating packaged in two parts prior

to application as follows:

1) Epoxy

resin that is cross linked

2) a co-reactant or hardener.

When

properly catalyzed and applied, epoxies produce a chemical and solvent

resistant finish. It is selection and mixture of the epoxy and hardener

components that determine the final characteristics and suitability of the

epoxy coating for a given requirement. These coatings are formulated on the

basis of the performance requirements of the final product.

1. Epoxy Coating for wall

Epoxy walls

are quick and easy to apply, and in no time create strong, hygienic and

easy-to-maintain surfaces that make your space look great. Particularly in

settings where chemical resistance, light reflectivity, and sanitation are

important; epoxy for walls is a perfect choice. It can prevent harmful bacteria

growth and resist moisture that leads to dangerous mold. This is important for

food preparation and handling areas, correctional facilities, locker rooms,

hospital operating rooms, veterinary clinics, and more.

Our epoxy wall coating systems are available in a number of different varieties and

colours, so you're sure to find a paint to meet your specific needs. With our

epoxy for walls, you won’t have to sacrifice style for functionality.

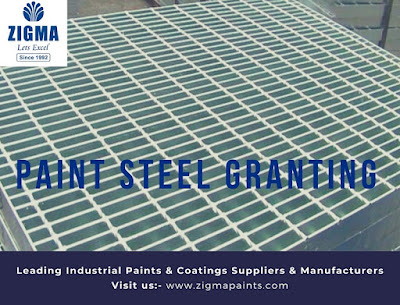

2. Epoxy Coating for Flooring

Epoxy Coating will result in a durable and long

lasting for flooring applications. Epoxy Coating used over floors in a variety

of industrial applications, such as manufacturing plants, commercial and retail

stores, industrial plants, warehouses, hospitals, showrooms and more. Epoxy

Coating floor paints provide a decorative and a high gloss finish that is

available in a variety of colors and styles.

It can be

applied by brush, roller and spray at surface or eminent temperature. Their

products useful for factory cast steel and cast aluminium applications, and

reduce exposure issues associated with solvent borne coatings.

The success

of Epoxy Powder Coating Paint by Zigma Paints Group is now enhanced by continuous innovations,

improved formulations, knowledge and advanced technology, so we are here to

provide specialised Epoxy Powder Coating

systems for a wide range of applications. We are a remarkable company,

engaged in providing a qualitative variety of other Industrial Paint Products

like Epoxy Primer, Epoxy Thinner to our clients.

Contact us:- (0253)

2381 429 / 660 2735

Visit us:-

www.zigmapaints.com/epoxy-powder-coating-paint.php